Описание

RS Series punch press machine is new generation for Servo Hydraulic series, inherited the features of high reliability and durability from series HP. With Germany H+L advanced servo hydraulic system, its powerful punching capacity is good for thick sheet. Multi-functional for punching, forming, roller cutting and tapping, substantial reduce the stand-by time and increase material utilization. Furthermore, high speed, high accuracy, energy saving, and high integrated assembly construction, efficient reduce maintenance cost.

Drive system

RS Series adapted with Germany H+L advanced servo-hydraulic system. The punching capacity 20 tons and 30 tons, maximal power supply 15KW. High integrated assembly construction and compact drive system, reducing 30% hydraulic oil, annual reducing maintenance cost and save consumption cost greatly.

RS Series adapted with Germany H+L advanced servo-hydraulic system. The punching capacity 20 tons and 30 tons, maximal power supply 15KW. High integrated assembly construction and compact drive system, reducing 30% hydraulic oil, annual reducing maintenance cost and save consumption cost greatly.

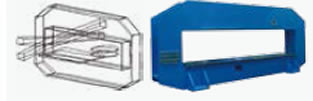

Closed O Shape Frame Structure

High Rigidity & High Stability

The closed O shape frame structure is analyzed by the "Finite Element Analysis" software to simulate stress / strain conditions to enable the optimal structure design.

High Tensile Strength Steel Construction

The machine frame is welded by high tensile strength steel, which is subject to high tensile strength tests, normalization treatment and vibration stress relief so as to ensure the machine assembling accuracy.

Transient State Analysis

Static Analysis

Model Analysis

Transient State Analysis

Технические характеристики

| Item | Unit | X23 |

|---|---|---|

| Punching Capacity | Tom | 30 |

| X Traverse Length | mm | 2500±10 |

| Y Traverse Length | mm | 1250±10 |

| Max Sheet Size | mm | 1250x4980 |

| Max Sheet Thickness | mm | 6.35 |

| Max Sheet Weight | kg | 110 |

| X Axis Traverse Speed | m/min | 100 |

| Y Axis Traverse Speed | m/min | 80 |

| Max Traverse Speed | m/min | 128 |

| Punching Speed at 25mm pitch* | hist/min | 450 |

| Nibbling Speed | hist/min | 1200 |

| Tools Type | Thick turret | |

| Max Punching Diameter | mm | 88.9 |

| Number of Tool Stations | 48 / 57 / 66 | |

| Number of Auto Index Stations | pcs(type) | 4(2B+2C) / 3(2B+1C) / 2(1B+1C) |

| Turret Rotating Speed | rpm | 33 |

| Auto Index Rotationg Speed | rpm | 100 |

| Ram Stroke Distance | mm | 0~31 |

| Working Tables Size | Brush | |

| Number of Sheet Clamps | pcs | 3 |

| Air Supply | NL/min | 250 |

| Air Supply | bar | 6 |

| Oil Tank Volume | Litre | 275 |

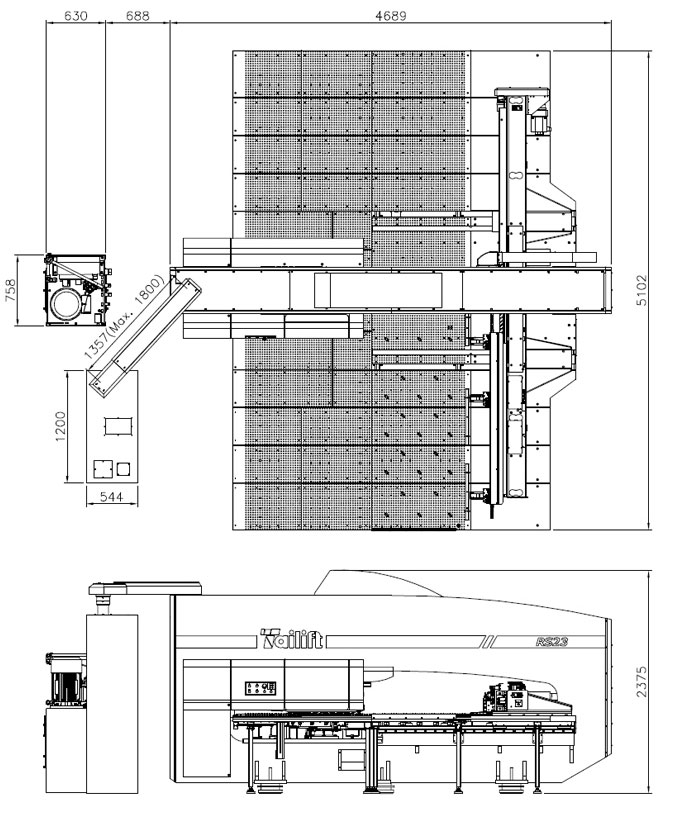

| Machine Dimension (L x W x H) | mm | 5940x5220x2420 |

| Net Weight (approx.) | kgf | 14,000 |

| Size of Control Cabinet | mm | 1350x700x2185 |

| CNC Controller | FANUC Oi-PD | |

| Number of Controllable Axes | Axis | 4 |

| RAM Memory | KB | 512 |

| Serial Interface | RS232/RJ45/PCMCIA | |

| Punching Precision* | mm | ±0.1 |

- Specifications are subjects to change without prior notice.

- Acceleration / deceleration rate of X / Y-axis are dependent on weight of materials.

- Punch speed depends on processing conditions, stroke length, acceleration / deceleration of

Инструментальная турель

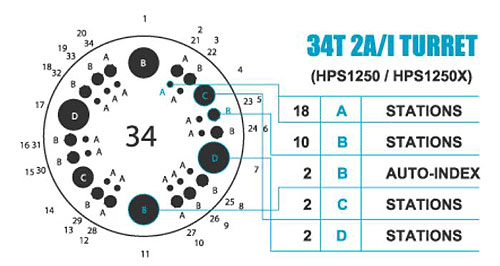

Turret with 34 Stations

- The turret is transmitted through the worm and worm gear mechanism.

Two shafts are synchronously transmitted via a connecting rod for safe and dependable positioning. - The turret is designed with 34 stations, and accommodates various tool sizes from 1/2" to 3-1/4". Changing tool size is available upon customer request.

- Each station can be fitted with various brand tools, such as Mate and Wilson.

- Designed with two circular track stations.

- Replaceable bushing easy to maintain.

| Atype (1/2") MAX diameter 12.75mm | 18 (4 accept shaped tools) |

| Btype (1-1/4") MAX diameter 31.75mm | 10 (10 accept shaped tools) |

| Btype (1-1/4") MAX diameter 31.75mm | 2 AUTO. INDEX |

| Ctype (2") MAX diameter 50.8mm | 2 (2 accept shaped tools) |

| Dtype (3-1/2") MAX diameter 88.9mm | 2 (2 accept shaped tools) |

Аксессуары

Standard

- Supporting Ball Set

- Anti-vibration Foot Mounts

- Sheet Distortion Sensor

- Heavy-duty Clamp

- Die Holder Brush

- Repositioning Cylinder

Optional

- CAD/CAM Software

- Tapping System

- Large Brush on Table

- Block Lowering Device

Чертёж